Dairy, Food & Beverages Industry Solutions by Verito Engineering Private Limited

At Verito Engineering Private Limited, we specialize in providing advanced

engineering solutions designed to enhance the efficiency, safety, and quality of production

processes in the Dairy, Food & Beverages Industry. Our state-of-the-art

Agitators/Mixers, Dosing/Metering Pumps, and Dosing Systems/Skid Injection Packages are

meticulously crafted to support the diverse needs of this industry—from milk processing to

beverage formulation and food manufacturing. With a focus on precision, hygiene, and regulatory

compliance, Verito ensures that your production line operates smoothly and

efficiently, meeting the highest standards of quality and food safety.

Key Applications of Verito Products in the Dairy, Food & Beverages Industry

1. Milk Processing and Homogenization

In dairy processing, maintaining product consistency, texture, and shelf life is paramount. Verito’s

Agitators and Dosing Pumps are integral to ensuring smooth milk homogenization and precise additive

mixing.

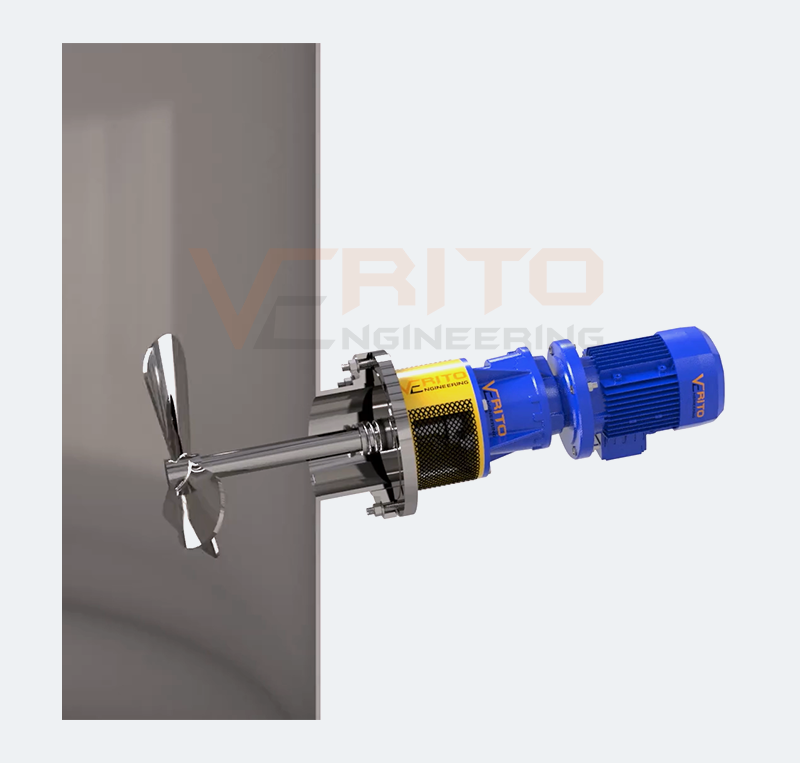

- Agitators for Milk Homogenization: Our high-performance agitators ensure even

dispersion of fat molecules, preventing separation and maintaining a smooth, creamy texture in

milk and other dairy products. Designed for gentle yet thorough mixing, these agitators enhance

product consistency while minimizing energy consumption.

- Dosing Pumps for Additives: Accurate dosing of essential additives such as

vitamins, stabilizers, and preservatives is critical for fortifying milk and other dairy

products. Verito’s Metering Pumps deliver precise quantities of these

additives, ensuring compliance with nutritional standards and improving product stability.

- Sludge Treatment: Our agitators help in the effective treatment and

stabilization of sludges generated during the production process.

2. Beverage Production and Ingredient Mixing

In the beverage industry, precise mixing and dosing are essential for achieving the desired taste,

color, and consistency. Verito’s Agitators/Mixers and Dosing Systems

are designed to meet the rigorous demands of beverage formulation.

- Mixers for Beverage Blending: Our mixers ensure uniform mixing of ingredients

such as syrups, flavors, colorants, and preservatives, leading to consistently high-quality

beverages. From soft drinks to juices and flavored waters, our equipment guarantees perfect

blending every time.

- Agitators for Fermented Beverages: In the production of fermented beverages

like beer and kombucha, our agitators optimize the fermentation process by ensuring even

distribution of yeast and nutrients, resulting in improved flavor and alcohol content control.

- Water Treatment Chemicals: Dosing of flocculants, coagulants, and pH adjusters

in water treatment processes for maintaining plant efficiency and compliance with environmental

standards.

3. Food Processing and Ingredient Blending

Food processing requires precise mixing and dosing to ensure uniformity and product quality across a

variety of applications, from dough kneading to sauce preparation. Verito’s Agitators and

Dosing Systems ensure efficient ingredient integration while maintaining product

integrity.

- Agitators for Food Mixing Our industrial agitators handle everything from

thick pastes to delicate liquids, ensuring even mixing of ingredients such as sauces, batters,

and marinades. With superior mixing performance, they help streamline food production processes

while improving product texture and quality.

- Dosing Systems for Ingredients and Flavors: Precise control over the addition

of ingredients like preservatives, colors, and seasonings is essential in food production.

Verito’s Dosing Systems provide accurate, automated dosing to ensure

consistent flavor profiles and safe, high-quality food products.

- Effluent Treatment: Dosing of treatment chemicals for handling wastewater

generated during cement production, ensuring that plants meet discharge regulations.

4. Cleaning and Sanitization Systems

Hygiene is paramount in the dairy, food, and beverage industries. Verito’s Dosing Systems play a

critical role in ensuring proper cleaning and sanitization, helping companies maintain regulatory

compliance and product safety.

- Dosing Pumps for CIP (Clean-In-Place) Systems: Our dosing pumps ensure

accurate injection of cleaning agents such as detergents, sanitizers, and disinfectants in

Clean-In-Place (CIP) systems. This ensures that equipment is thoroughly cleaned and sanitized,

preventing cross-contamination and ensuring food safety.

- Packaging and Preservation: In the final stages of production, precision is key

to ensuring that products are packaged safely and retain their quality throughout their shelf

life. Verito’s Dosing Systems support efficient and consistent dosing of preservatives and other

agents in food and beverage packaging.

- Dosing Systems for Packaging Additives: Precise dosing of anti-caking agents,

stabilizers, and preservatives ensures that packaged products remain fresh and maintain their

quality during storage and transport. Verito’s Dosing Pumps provide the

accuracy and reliability needed to meet packaging and preservation standards.

Why Choose Verito Engineering for Dairy, Food & Beverages Industry Solutions?

- Industry Expertise: With deep experience in serving the Dairy, Food, and

Beverages industry, Verito understands the strict hygiene standards,

regulatory requirements, and technical challenges of food production

- Precision and Reliability: Our dosing pumps and agitators offer precise

control over mixing and chemical dosing, reducing product waste and ensuring consistent quality.

- Hygiene-Centric Design: Our products are designed for easy cleaning and

maintenance, ensuring the highest levels of hygiene, which is essential in food and beverage

production.

- Customizable Solutions: We offer fully customizable systems to meet the

specific production requirements of your dairy, food, or beverage facility, whether you're

handling small batches or large-scale manufacturing.

- Compliance and Sustainability: Verito solutions help producers meet stringent

industry regulations while promoting sustainable practices through efficient resource usage and

waste reduction.

Optimize Your Dairy, Food & Beverage Production with Verito

From milk processing to beverage formulation and food packaging, Verito Engineering Private

Limited offers cutting-edge equipment to enhance your production capabilities. Our

Agitators/Mixers, Dosing Pumps, and Dosing Systems are designed to meet the

unique demands of the Dairy, Food & Beverages industry, delivering precision, reliability, and

hygiene in every process.

Contact us today to learn how Verito can help you optimize your dairy, food, and

beverage production processes with our industry-leading engineering solutions.