TBHQ (tert-Butylhydroquinone):

Antioxidant: TBHQ is an antioxidant commonly used in the food industry to

prevent the oxidation of fats and oils, extending the shelf life of processed foods.

Stabilizer: It is also used as a stabilizer in certain industrial processes,

such as the production of certain polymers and resins.

Vitamin D:

Food Fortification: Vitamin D is often added to various food products to

fortify them, contributing to the nutritional content of the food.

Health Supplements: In the pharmaceutical industry, Vitamin D is used in the

production of health supplements to address deficiencies and promote bone health.

Key components and features of a TBHQ and Vitamin Dosing System may include:

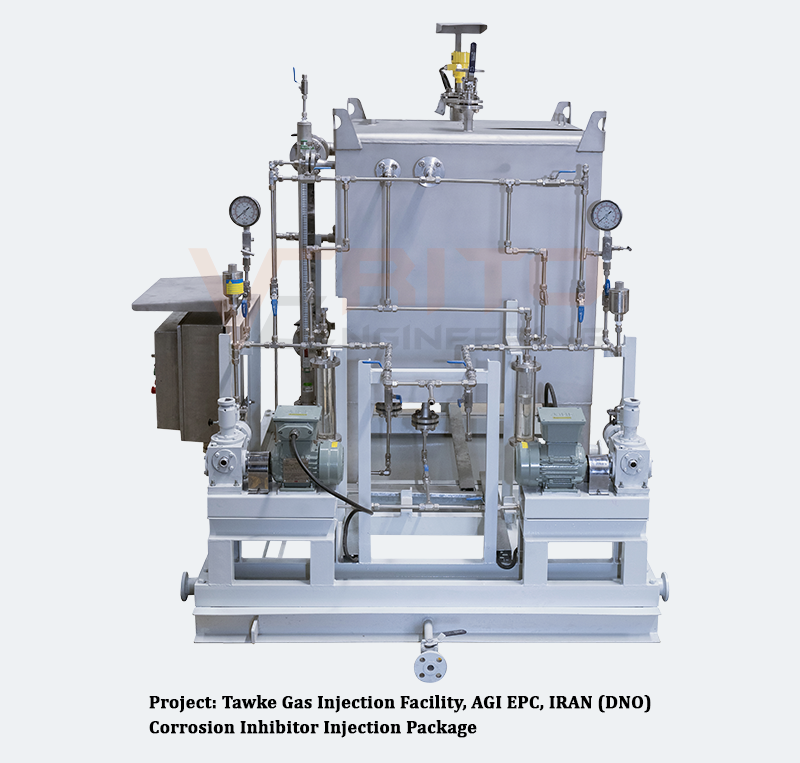

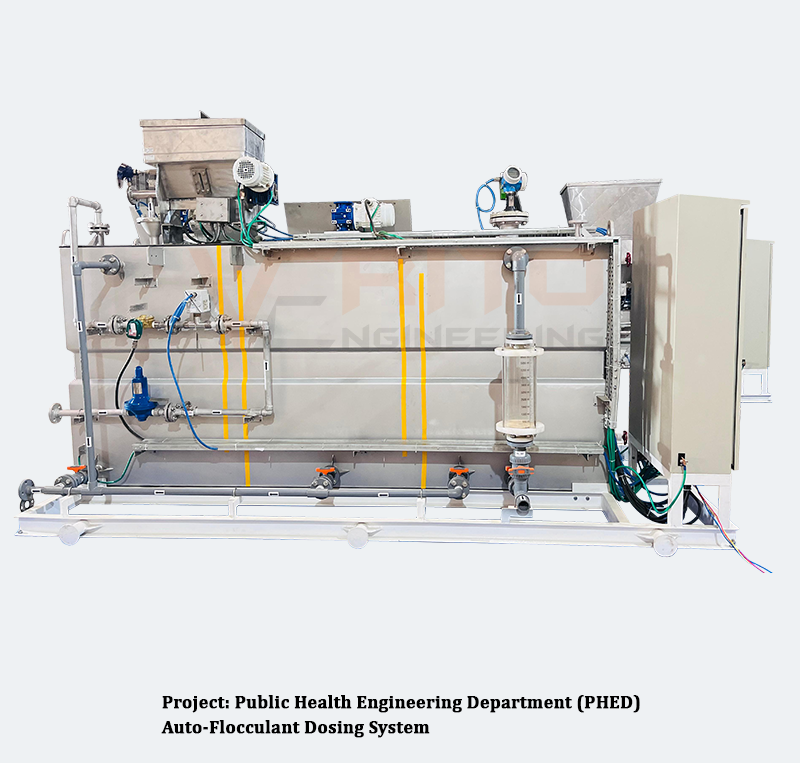

Storage Tanks: Separate tanks for TBHQ and Vitamin D solutions, each

tailored to the specific requirements of the dosing application.

Dosing Pumps: Individual dosing pumps for TBHQ and Vitamin D that

accurately inject or dose the required amount of each substance into the process stream. The dosing

pumps ensure precision and control in the dosage.

Agitator: The agitator serves to mechanically mix and disperse the solution

within the process stream. This ensures that the substance is thoroughly integrated, promoting

efficient reactions and achieving uniform pH adjustment or chemical balance.

Control System: A control unit manages the dosing rates for TBHQ and

Vitamin D based on various parameters, such as the composition of the processed material,

nutritional requirements, or specific process conditions.

Safety Features: As with any dosing system, safety features may be

integrated, including leak detection systems, emergency shutdown mechanisms, or proper ventilation,

depending on the nature of the substances being dosed.

Applications of a TBHQ and Vitamin Dosing System may vary:

Food Industry: TBHQ is commonly used in the food industry to preserve the

quality of fats and oils, while Vitamin D is added to various food products for nutritional

fortification.

Pharmaceutical Manufacturing: Vitamin D is an essential ingredient in the

production of pharmaceutical supplements.

Chemical Processing: TBHQ may be used as a stabilizer in certain chemical

processes.