- Home

- About Us

-

Our Products

- Dosing Pumps

- Agitator

- Mineral Slurry Agitator

- Chemical Reactor Agitator

- Flue Gas Desulfurization (FGD) Agitator

- Side Entry Agitator for Digestor Tank (Bio Gas Plant)

- Multi-Axial (Triple Shaft) Agitators

- Agitator for Distillery Fermentation Tanks

- Agitators for Pharmaceutical Industry

- Agitators for Dairy Industry

- Side Entry Agitator for Food-Processing Storage Tanks

- Reactor Agitator

- Heavy Duty Agitators

- Flocculators Sludge Agitators

- High Speed Agitators

- Agitators for small volume

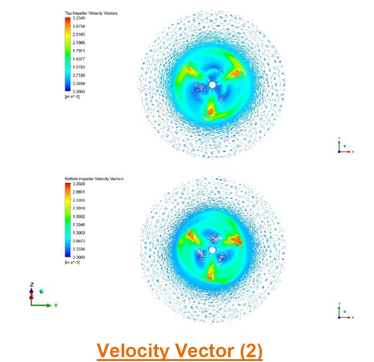

- Mixing Impeller

- Dosing System / Chemical Injection Packages

- Additive Injection Packages for JET Fuel System

- Octane Booster

- Polymer Auto Dissolving Dosing System

- Disulfide Oil (DSO) Process Dosing Skid

- Dimethyl Disulfide (DMDS) Injection Package

- Mercaptan Dosing Systems

- Corrosion Inhibitor Injection Package

- PH Correction Injection Package

- KOH Circulation System

- Additive Chemical Injection Package

- Anti Bleeding Chemical Injection Package

- Chemical Dosing System

- Stadis 450 Injection Package

- Auto-Polyelectrolyte Dosing System

- LP Dosing Systems

- HP Dosing System

- Aqueous Ammonia Injection Skid

- Diesel Dosing Systems

- Anti-Foaming Injection Package

- Ammonia Dosing System

- TBHQ & Vitamin Dosing System

- UV Sterilizer Pneumatic Water Treatment System

- CLO2 Dosing System

- Auto-Focculant Dosing System

- Zycotherm Dosing Skid

- Lime Dosing System

- Poly Dosing System

- Coagulant Dosing System

- CEB-UF Hypo Dosing System

- FeCL3 Dosing System

- HCL Dosing System

- NaOCl Dosing System

- Antiscalant Dosing System

- SMBS Dosing System

- NaOH Dosing System

- Polymer Dosing System

- Liquid Dosing System

- Injection Quill

- Accessories

- Strainers

- Industries

- Clients

- Infrastructure

- Career

- Blogs

- Contact us