Key components and features of a Liquid Dosing System typically include:

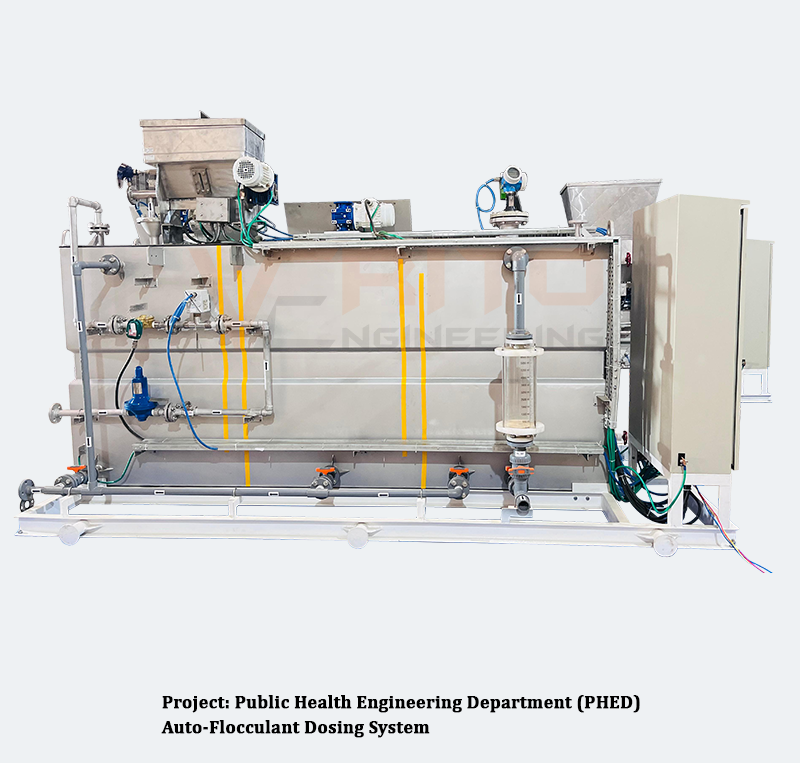

Liquid Storage Tank: The system includes a storage tank where the liquid

chemical is stored. The tank's capacity and design depend on the volume and properties of the liquid

being dosed.

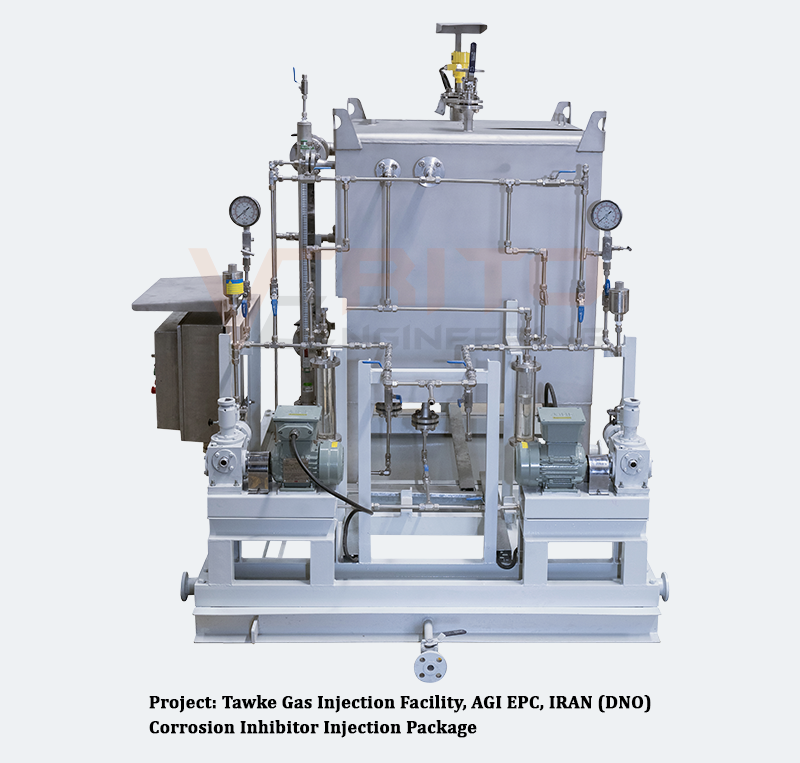

Dosing Pump: A dosing pump is a crucial component that accurately injects or

doses the required amount of liquid into the process stream. The dosing pump ensures precision and

control in the dosage.

Control System: A control unit manages the dosing rate based on various

parameters such as flow rate, concentration, or specific process conditions. This control system

helps maintain the desired level of the liquid chemical in the industrial process.

Safety Features: Depending on the nature of the liquid chemical being dosed,

safety features may be integrated, such as leak detection systems, emergency shutdown mechanisms, or

proper ventilation to ensure the safety of personnel and the environment.

Liquid Dosing Systems find application in various industries and processes:

Water Treatment: Liquid chemicals such as coagulants, flocculants,

disinfectants, and pH adjusters are commonly dosed in water treatment plants for purification and

disinfection.

Chemical Manufacturing: In chemical production processes, liquid dosing

systems are used to add specific chemicals or reagents at controlled rates.

Food and Beverage Industry: Liquid dosing systems may be employed to add

ingredients, additives, or sanitizing solutions in food and beverage processing.

Pharmaceutical Manufacturing: Liquid dosing is essential in pharmaceutical

production for accurate dispensing of ingredients and active pharmaceutical components.

Industrial Processes: Various industrial processes, such as cooling water

treatment, metal processing, and textile manufacturing, may utilize liquid dosing systems for

specific chemical applications.