Upstream Applications

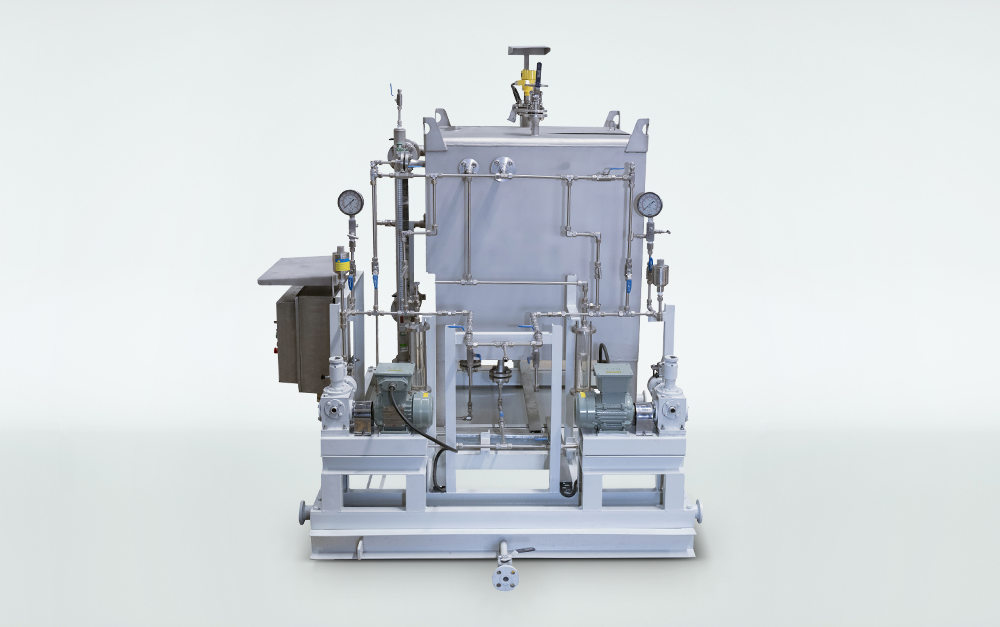

In the upstream sector, ensuring flow assurance and equipment integrity is

critical. Verito Engineering's metering pumps and skid-mounted injection

packages inject chemicals like methanol to prevent hydrate formation

and

corrosion inhibitors to protect well infrastructure. Additionally, we provide

dosing systems for demulsifiers and paraffin inhibitors, helping

operators

optimize oil flow and maintain efficient well performance in both onshore and

offshore environments.

Midstream Applications

For the transportation and storage of oil and gas, protecting pipelines and

maintaining product quality are top priorities. Verito’s corrosion inhibitor

dosing systems safeguard pipelines during the midstream phase, while our

agitators/mixers ensure uniform blending in FPSO units and storage

tanks. We

also offer mercaptan dosing systems, essential for odorizing natural

gas to

ensure safety in midstream distribution, meeting industry compliance and safety

standards.

Downstream Applications

In downstream operations, precise chemical injection is key to refining and

petrochemical processes. Verito’s dosing pumps are designed to handle a range of

chemicals, such as caustic soda, acids, and

catalysts, used in crude oil

desalting, distillation, and product separation. Our

mixers prevent settling and

deposit formation in refined products, ensuring consistent quality and

operational efficiency. Our equipment also supports additive dosing systems,

including coloring agents and antioxidants for fuel treatment.

Produced Water Treatment

Verito Engineering specializes in systems that treat produced water, which is a

byproduct of oil extraction. Our dosing systems handle the injection of

chemicals like biocides, scale inhibitors, sodium

hypochlorite, and oxygen

scavengers, ensuring effective water treatment and reducing environmental

impact. These systems help operators achieve regulatory compliance and extend

the operational life of water treatment infrastructure.

Gas Odorization (Mercaptan Dosing)

Safety in natural gas distribution is critical, and mercaptan dosing systems play

an essential role in adding an odor to the otherwise odorless gas, ensuring any

leaks are easily detectable. Verito’s precise mercaptan dosing solutions are

designed to meet stringent safety standards, providing reliable and controlled

odorant injection for gas processing and distribution networks, both onshore and

offshore.

Chemical Injection for Pipeline Integrity

Maintaining the structural integrity of pipelines is crucial in both upstream and

midstream operations. Verito’s chemical injection systems deliver accurate

dosing of scale inhibitors, wax dispersants, asphaltene

inhibitors, and

corrosion inhibitors, protecting the pipeline network from build-up, blockages,

and corrosion that could impact flow efficiency and safety.

Why Verito Engineering?

- Tailored Solutions: We provide custom-designed systems that

address specific operational needs in oil and gas applications, ensuring

precision, reliability, and long-term performance.

- Versatility Across Environments: Our equipment is built to

perform in the toughest conditions—whether offshore in corrosive

environments or in extreme temperatures, from desert oilfields to arctic

regions.

- Unmatched Expertise: With deep technical knowledge, we

ensure every product is designed and tested to meet industry regulations and

optimize your operations.

Conclusion

Verito Engineering is your trusted partner for end-to-end solutions in the oil &

gas industry. From mercaptan dosing systems to corrosion inhibitor injection,

our products are engineered to deliver superior performance across the upstream,

midstream, and downstream sectors. With our innovative technology and industry

expertise, we help you enhance operational efficiency while meeting safety and

regulatory standards.

Contact Verito Engineering today to learn more about how we can tailor solutions

to your oil & gas operation.