Boiler Water Treatment (LP & HP Systems)

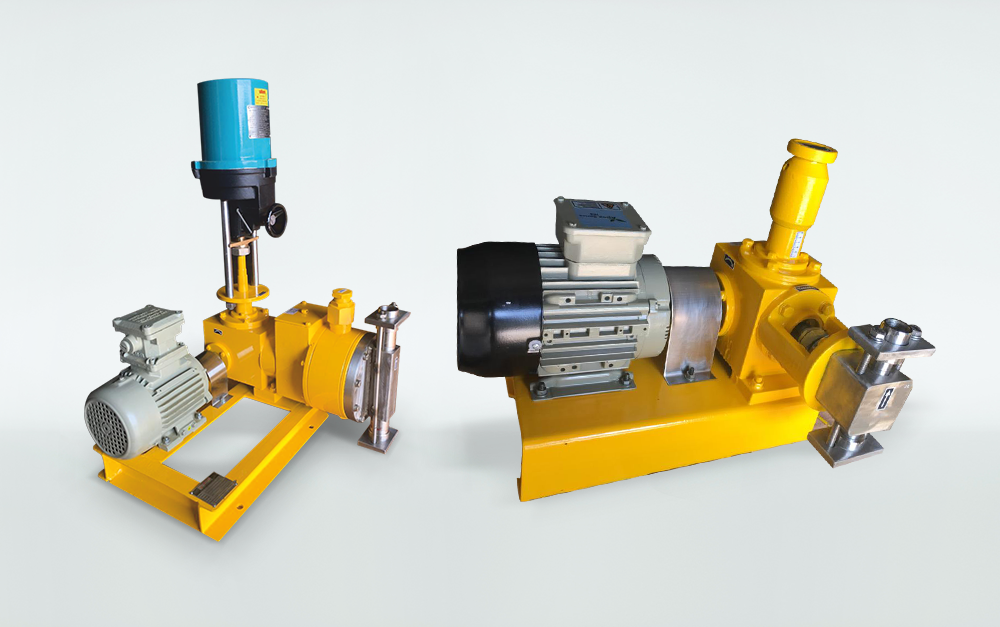

In both low-pressure (LP) and high-pressure (HP) boiler systems, maintaining water

purity is essential to prevent corrosion and scale formation, which can lead to costly downtime.

Verito’s Dosing/Metering Pumps ensure accurate dosing of key chemicals like oxygen

scavengers (Hydrazine), phosphates, and anti-scalants to maintain boiler integrity.

Our Injection Quills provide precise chemical delivery directly into the

feedwater system, ensuring even distribution and protection against corrosion and deposits in both

LP and HP boilers, enhancing operational longevity.

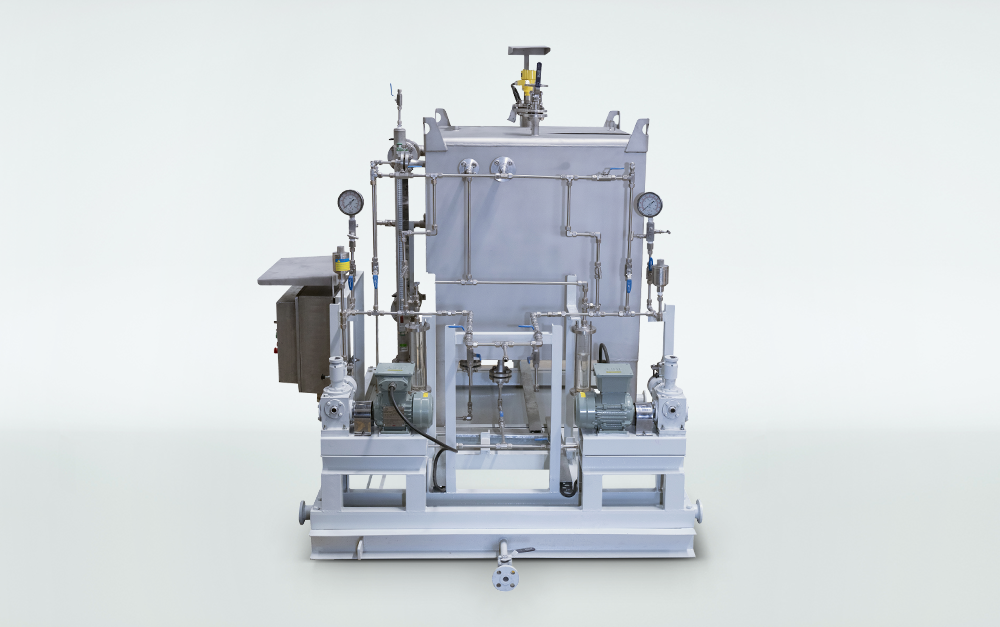

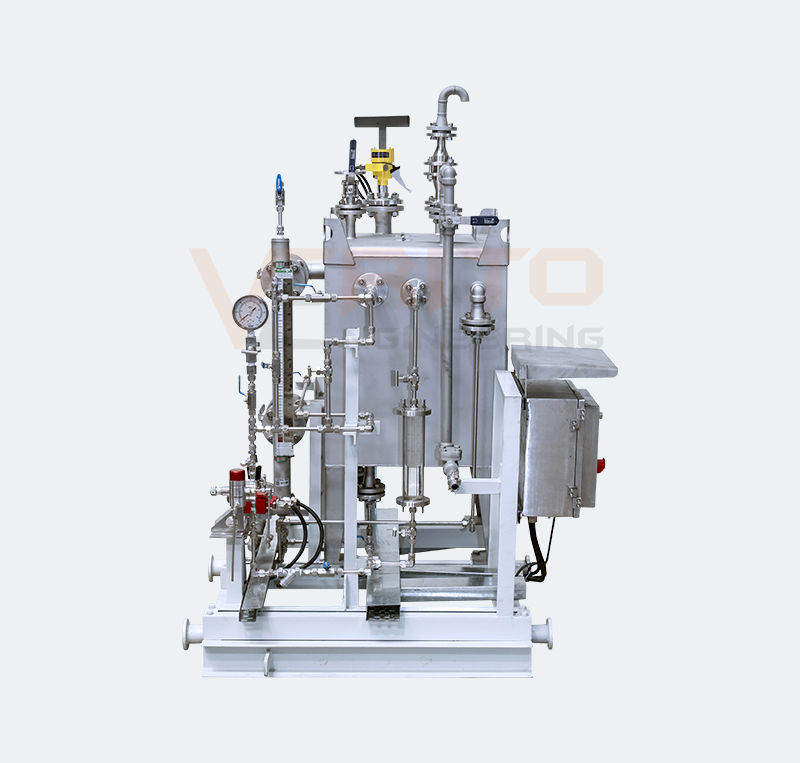

Hydrazine and Oxygen Scavenger Injection

Hydrazine injection is a critical process in power plants for removing dissolved oxygen in boiler

feedwater, especially in high-pressure steam systems. Verito’s metering pumps

provide precise hydrazine dosing, preventing oxidation and corrosion in

high-temperature environments. Our skid-mounted dosing systems ensure safe,

reliable hydrazine injection, reducing the risk of system degradation and improving overall plant

efficiency.

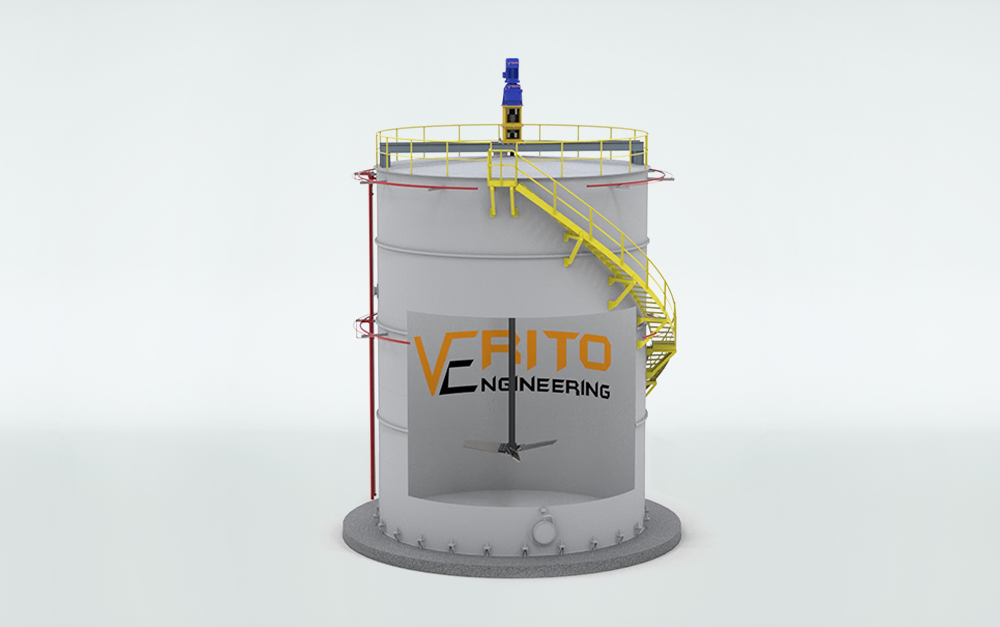

Cooling Water Treatment

Effective cooling water treatment is essential to prevent scaling, corrosion, and biofouling in

cooling towers and condensers. Verito’s Dosing Pumps precisely inject

biocides, anti-scalants, and corrosion inhibitors into the cooling water system,

safeguarding your plant's cooling infrastructure. Our Agitators/Mixers ensure uniform distribution

of chemicals within large cooling reservoirs, preventing localized corrosion and maintaining

operational efficiency.

Flue Gas Desulfurization (FGD)

Flue gas desulfurization (FGD) systems are critical for reducing SOx emissions from power plants.

Verito’s Dosing/Metering Pumps deliver precise doses of lime slurry,

magnesium oxide, and other reagents to remove sulfur dioxide from flue gases. Our

Mixers/Agitators ensure effective mixing of reagents in FGD tanks, promoting efficient chemical

reactions and reducing emissions, helping power plants meet stringent environmental regulations.

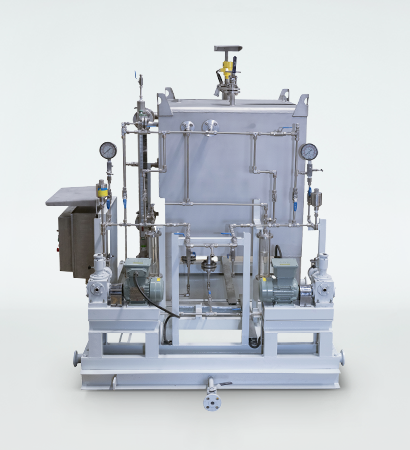

Chemical Injection for Combustion Optimization

Power plants need precise chemical injection for optimizing combustion processes, especially in

coal-fired and natural gas plants. Verito’s Skid

Injection Packages provide complete, turnkey solutions for the accurate dosing of

combustion enhancers, such as ammonia, urea, and limestone slurry,

ensuring optimal fuel burn rates and reducing NOx emissions. Our systems are customized to

integrate seamlessly into your plant’s existing infrastructure.

Effluent Treatment

Effluent management is essential for regulatory compliance in power plants. Verito’s Dosing

Pumps handle the precise injection of chemicals like pH adjusters, coagulants,

and flocculants into effluent streams, ensuring efficient treatment before discharge.

Our Agitators enhance the mixing of chemicals within large treatment tanks, improving the efficiency

of solid-liquid separation processes and ensuring clean water discharge in compliance with

environmental standards.

Why Verito Engineering for Power Plant Solutions?

- Precision and Reliability Our dosing systems ensure accurate chemical

injection, improving process efficiency and reducing chemical wastage, which is crucial for

maintaining operational excellence.

- Customized Systems We offer tailored solutions that integrate seamlessly with

your power plant’s existing systems, optimizing chemical handling processes from boiler water

treatment to emissions control.

- Durable and Robust Design Our equipment is built to handle harsh environments,

ensuring long-term reliability and reduced maintenance in power plant operations.

- Compliance with Environmental Standards Our solutions, including dosing systems

for FGD and effluent treatment, help power plants comply with stringent emissions and wastewater

discharge regulations.

Conclusion

Verito Engineering’s products are trusted by power plants worldwide to ensure efficient, reliable

operations. From precise chemical dosing for water treatment to

effective mixing in FGD systems, our solutions play a crucial role in maintaining the

performance, safety, and regulatory compliance of power generation facilities.

Contact us today to learn how Verito Engineering can help optimize your power

plant’s operations with our advanced chemical dosing and mixing solutions.